Table of Contents

TogglePackaging Requirements for Export Goods

Introduction

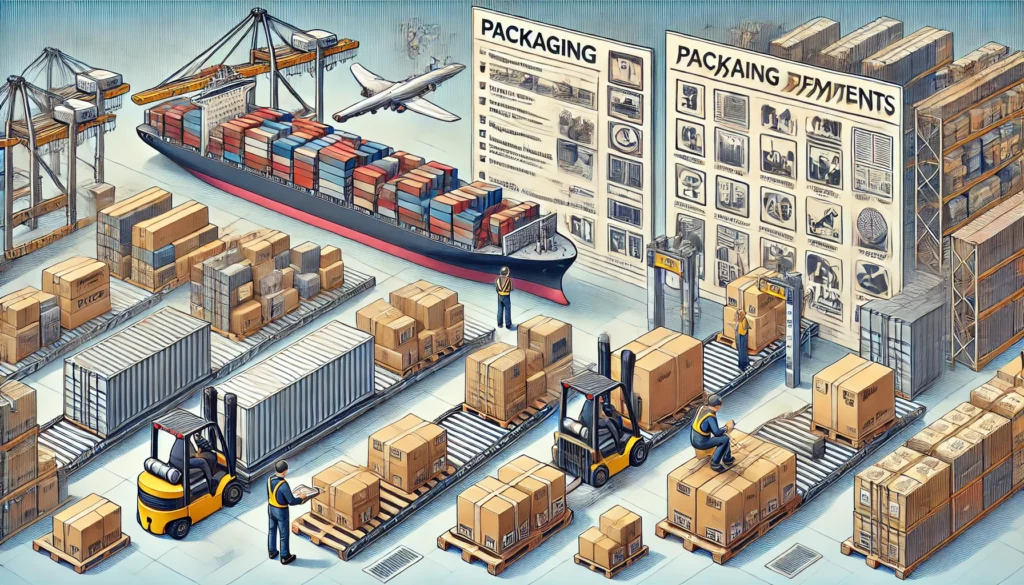

Packaging plays a crucial role in international trade, ensuring that goods reach their destination in optimal condition. Proper packaging not only protects products from damage but also complies with international regulations, enhances brand perception, and facilitates smooth customs clearance. This blog provides an in-depth guide to packaging requirements for export goods, covering legal regulations, industry standards, and best practices.

Importance of Packaging in Export

Product Protection – Prevents physical damage, contamination, and spoilage.

Compliance with Regulations – Ensures adherence to international packaging laws and standards.

Ease of Handling and Transportation – Facilitates efficient loading, unloading, and storage.

Branding and Marketing – Enhances product visibility and customer trust.

Cost Efficiency – Reduces waste, shipping costs, and potential rejections at customs.

Types of Packaging for Export

1. Primary Packaging

Directly encloses the product (e.g., bottles, cans, blister packs, cartons).

Ensures product freshness and integrity.

2. Secondary Packaging

Groups multiple primary packages (e.g., shrink wrap, boxes, trays).

Facilitates handling and provides additional protection.

3. Tertiary Packaging

Bulk packaging for transport (e.g., pallets, crates, drums, containers).

Ensures stability during shipping and warehousing.

International Packaging Standards and Regulations

1. ISPM-15 (International Standards for Phytosanitary Measures No. 15)

Applies to wooden packaging materials such as pallets and crates.

Requires heat treatment or fumigation to prevent the spread of pests.

Marking with the ISPM-15 stamp is mandatory for compliance.

2. UN Packaging Regulations for Hazardous Goods

Governs packaging for chemicals, pharmaceuticals, and flammable materials.

Requires specific labeling, cushioning, and leak-proof containment.

3. EU Packaging and Waste Regulations

Imposes limits on packaging waste and encourages recyclability.

Restricts hazardous substances in packaging materials.

4. FDA and USDA Packaging Standards (For Food Exports to the U.S.)

Requires food-grade, tamper-proof, and properly labeled packaging.

Ensures compliance with hygiene and safety regulations.

5. Country-Specific Packaging Rules

Vary by country and industry (e.g., labeling requirements, language specifications, recycling laws).

Key Elements of Export Packaging

1. Material Selection

Common materials: Cardboard, plastic, wood, metal, glass.

Factors to consider: Durability, weight, environmental impact, cost.

2. Protection Against Physical Damage

Use of shock-absorbing materials like bubble wrap, foam, and air pillows.

Reinforced corners and double-layered boxes for fragile items.

3. Moisture and Climate Resistance

Waterproof packaging for humid and wet conditions.

Desiccants (silica gel) to absorb moisture.

UV-resistant coatings for sun-sensitive goods.

4. Tamper-Proof and Security Features

Seals, holograms, and RFID tags to prevent counterfeiting.

Secure strapping for high-value shipments.

5. Labeling and Marking Requirements

Essential details: Product name, country of origin, weight, handling instructions.

Compliance with international labeling laws (e.g., CE marking, FDA-approved labels).

Barcoding for tracking and inventory management.

Best Practices for Export Packaging

Use Standardized Packaging – Reduces costs and simplifies logistics.

Optimize Packaging Size – Minimizes shipping expenses while ensuring product protection.

Ensure Easy Handling – Design packaging with grip points for efficient transportation.

Consider Sustainable Packaging – Use biodegradable materials to comply with environmental regulations.

Conduct Packaging Tests – Perform drop tests, vibration tests, and compression tests to assess durability.

Ensure Legal Compliance – Stay updated with international packaging regulations to avoid delays or penalties.

Conclusion

Proper packaging is essential for the success of any export business. By adhering to international standards, selecting the right materials, and optimizing design, exporters can safeguard their products, enhance customer satisfaction, and ensure seamless global trade operations. Investing in quality packaging is not just a regulatory requirement but a strategic move to gain a competitive edge in international markets.